Electronic Fuel Injection System Pdf Download

Aug. 05, 1996

Toyota Develops New D-4 Fuel Efficient,

High Output Direct-Injection Gasoline Engine

Sales of Vehicles Equipped with the D-4 Engine to Start this Year

Tokyo―TOYOTA MOTOR CORPORATION (TMC) announced today that it recently completed development of the D-4 direct-injection, 4-stroke gasoline engine. Sales of vehicles mounted with the Toyota D-4 engine will start within this year.

Toyota has long been successful in introducing environmentally friendly vehicles, especially those that involve fuel efficient and low-emission technologies. In 1984, TMC was the first in the world to begin mass production of a lean-burn engine.

The D-4 2.0-liter engine is the result of Toyota's efforts to develop engine technology in direct fuel injection, combustion, precise engine control, catalysts, and increased performance. It is the world's first engine capable of running with ultra-lean combustion ratios (air-fuel ratio: 50:1) using regular unleaded gasoline, and is designed to achieve significantly lower fuel consumption, higher output, and cleaner emissions than previously possible.

Direct fuel injection gasoline engines offer ultra-lean fuel combustion as fuel is directly injected into the cylinders in close proximity to the spark plugs. Forming the optimal air-fuel mixture―very lean, yet stable―however, requires a high level of technology. To accomplish this, Toyota developed high-pressure swirl fuel injectors, helical intake ports, electronic swirl control valves (E-SCV), lipped combustion chambers set into the top of the pistons, and various other technologies to produce stable, ultra-lean combustion. By combining these developments with VVT-i* and a three-way NOx storage/reduction catalyst, low fuel consumption, low NOx levels, and higher output have been achieved.

- *VVT-i (variable valve timing-intelligent)

- a continuously variable valve timing mechanism

Toyota will mount the 2.0-liter D-4 engine on automatic transmission vehicles, whose exhaust emissions are generally more difficult to control. In-house 10-15 mode tests showed that, compared to conventional engines, the D-4 provides at least 30% lower fuel consumption and 10% improvement in torque for better acceleration in the low- to mid-rpm range.

Toyota plans to market a very-low-fuel-consumption model equipped with the D-4 engine within the year.

Toyota D-4 Engine Overview

- Features

The Toyota D-4 injects fuel directly into the cylinders, achieving ultra-lean combustion for ultra-low fuel consumption, high output, and high responsiveness. The engine has the following innovations

-

- ULTRA-LOW FUEL CONSUMPTION THROUGH STRATIFICATION OF THE AIR-FUEL MIXTURE

-

Using a high-pressure swirl fuel injector, fuel injected directly before ignition at the end of the compression stroke is vaporized, while diffusion is controlled by air swirl from the helical intake port and the lipped combustion chamber in the top of the piston. The air-fuel mixture is thus stratified, concentrating the vaporized fuel around the spark plug and surrounding it with a much leaner mixture.

These air-fuel mixture strata provide stable combustion, and enable ultra-lean combustion operation with an air-fuel ratio (the weight ratio of air to fuel) of more than 50:1 throughout the cylinders. The engine's fuel consumption is 30% lower than that of conventional engines.

-

- HIGH OUTPUT, HIGH RESPONSIVENESS

-

Through vaporization of the directly injected fuel, an air intake cooling effect is created. Combined with VVT-i, which brings in air at the optimal moment, the cooler air allows for improved volumetric efficiency. As a result, although the engine runs on regular gasoline, it has a compression ratio of 10:1, for torque improvement in the low- to mid-rpm range of 10% over conventional engines. In addition, since direct fuel injection provides a rapid fuel supply, the D-4 provides better accelerator responsiveness.

-

- CLEAN EXHAUST

-

Direct fuel injection engines tend to produce a large amount of NOx emissions. The D-4 controls generation of NOx by using an exhaust gas recirculation (EGR) system for large volume and precise control. VVT-i technology, with its internal EGR effect, works to reduce Nox even further. The engine achieves clean emissions using a three-way NOx storage/reduction catalyst that neutralizes NOx produced during ultra-lean combustion, and also purifies HC and CO.

-

Comparison of D-4, Lean-Burn, and Conventional Engines*

| D-4 engine | Toyota lean-burn engine | Conventional engine | |

|---|---|---|---|

| Air-fuel ratio | About 50:1 | About 24:1 | About 15:1 |

| Air-fuel mixture | Stratified air-fuel mixture | Homogenous air-fuel mixture | Homogenous air-fuel mixture |

| Fuel injection | In-cylinder high-pressure injection | In-port low pressure injection | In-port low pressure injection |

| Air intake port shape | Helical | Helical | Straight |

| Catalyst | Three-way + Three-way NOx storage/reduction | Three-way NOx storage/reduction | Three-way |

- System Configuration

-

- High-pressure swirl injector

- Rapid fuel injection and ultra-fine fuel atomization.

-

- Lipped combustion chamber in the piston head

- Controls formation of the air-fuel mixture and spread of combustion.

-

- Helical intake port and E-SCV

- The E-SCV determines how much air flows through the helical intake port, thereby controlling the strength of horizontal air swirl.

-

- Engine control computer

- Precisely controls the timing and volume of fuel injected to match engine load and rpm.

-

- Electronic throttle valve

- Automatically opens and closes precisely in response to driving conditions, to provide smooth acceleration for all types of combustion.

-

- VVT-i

- Continuously controls the intake valve timing to match the engine speed and take advantage of the inertial charging effect, thus maximizing intake efficiency. Improves torque, power, and fuel consumption, and reduces NOx and HC.

-

- Three-way NOx storage/reduction catalyst

- Purifies occluded NOx at the stoichiometric air-fuel ratio after temporary NOx storage during lean combustion.

-

- New Technology

-

- Ultra-low fuel consumption by stratification of air-fuel mixture The different concentrations of air-fuel mixture are stratified within the cylinder, with a fuel-rich mixture in the area surrounding the spark plug and a mostly air mixture near the cylinder wall. Thus, although the overall air-fuel mixture in the cylinder is extremely lean, the stratified layer around the spark plug is fuel rich, allowing for stable combustion.

- Additionally, the large amounts of air that are possible through stratification help to reduce pumping loss and minimize thermal efficiency loss, further boosting fuel efficiency.

-

- Shape of combustion chamber for formation of air-fuel mixture Lipped edges facing the injection side prevent the fuel spray from leaving the combustion chamber in the piston crown. The chamber is shaped so that splashed back fuel vapor is led toward the vicinity of the spark plugs.

-

- Stable in-cylinder intake flow through helical ports

- The D-4 engine generates horizontal swirl in the cylinders to help stabilize combustion by stratifying fuel and air, leading fuel to the vicinity of the spark plugs. Fuel consumption and output are optimized by precisely altering the strength of the swirl according to driving conditions.

-

- Very fine spray

- Fuel is injected rapidly at a pressure approximately 40 times higher than that of conventional fuel injection valves and is almost instantly vaporized to facilitate combustion, resulting in less fuel diffusion and improved stratification.

-

- Precise fuel injection control

- To position the fuel-rich strata in the vicinity of the spark plugs, fuel is injected near the top of the compression stroke, before it has a chance to disperse, but after it has reached a stable air-fuel ratio.

At times when large amounts of fuel are needed, such as during acceleration, fuel is injected at the beginning of the intake stroke, and the air-fuel mixture in the combustion chamber becomes homogenous.

At cross-over points between homogeneous and stratified mixtures, a semi-stratified mixture is created for smooth torque transition. Precise control of the fuel supply is necessary to achieve stability in these various optimum combustion levels.

- Effects

-

- Fuel efficiency

- Automatic transmission vehicles with the Toyota D-4 engine achieve at least a 30% improvement in fuel consumption over vehicles with conventional engines (in-house 10・15 mode test).

-

-

- Acceleration

- The acceleration performance of vehicles with the D-4 engine is about 10% quicker than vehicles with conventional engines, both for standing-start and passing acceleration (in-house test).

- Major Specifications

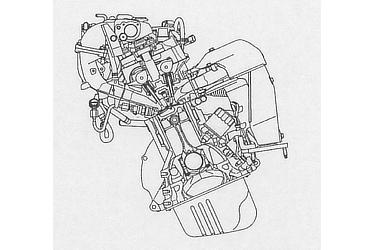

Engine Cross Section

Downloads (Images)

-

-

- Engine Cross Section

-

Posted by: talithatalithavaghne0268743.blogspot.com

Source: https://global.toyota/en/detail/7901843

Post a Comment for "Electronic Fuel Injection System Pdf Download"